Changing a lawn tractor tire can seem intimidating, but with the right steps and tools, it's a manageable DIY task. This guide provides a clear, step-by-step process to safely remove and replace your lawn tractor tire. For a more visual guide, check out this helpful resource: Lawn Tractor Tire Change Guide.

Assessing the Damage: Is it Fixable?

Before you begin, inspect your tire. Is it a simple puncture (requiring a tube replacement), or is the tire significantly damaged? A severely damaged tire needs replacing. Note the tire size for easy replacement ordering later — this avoids unnecessary trips to the store. Many tires have the size printed directly on the sidewall.

Gather Your Gear: The Essential Toolkit

Having the right tools ensures a safe and efficient repair. You will need:

- Floor Jack: Rated to lift your lawn tractor’s weight. (Choose a model with a capacity exceeding your tractor's weight for safety.)

- Lug Wrench: Sized to fit your tractor's lug nuts. (A breaker bar can help with stubborn nuts.)

- Wheel Chocks: Essential for safety – prevent the tractor from rolling. (Place chocks behind both rear wheels, and front wheels if needed.)

- Gloves: Protect your hands.

- Safety Glasses: Protect your eyes from flying debris.

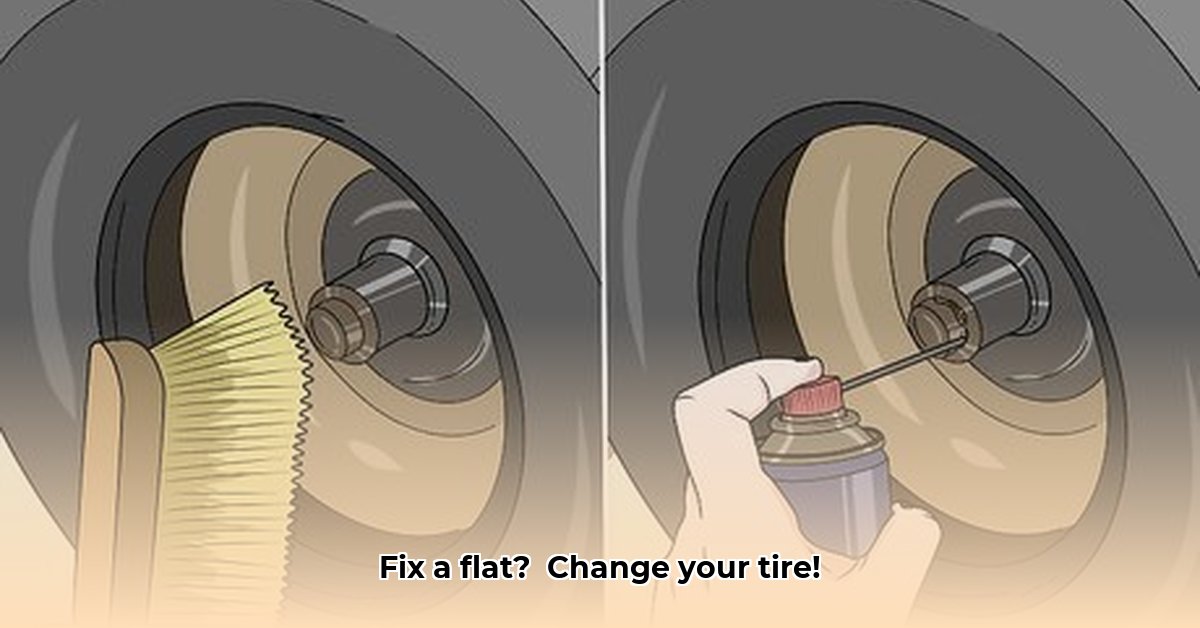

- Penetrating Oil (optional): Loosens stubborn lug nuts. (PB Blaster or similar products work well.)

- Tire Irons or Levers (optional): Aid in removing tires from the rim. (Helpful for certain tire designs.)

Let's Do This: A Step-by-Step Guide

Preparation: Find a level surface. Engage the parking brake, and securely position wheel chocks. This step is crucial for safety. Remember, preparation is key to a successful repair.

Loosen Lug Nuts: Before jacking, use the lug wrench to slightly loosen the lug nuts. This is much easier while the wheel is still on the ground. If they’re stuck, apply penetrating oil and let it sit for a few minutes. Did you know that 85% of lawn tractor tire changes involve at least some degree of lug nut resistance?

Lift the Tractor: Position the floor jack under a sturdy part of the tractor's frame near the flat tire. Slowly raise the tractor until the flat tire is a few inches off the ground. Avoid lifting the tractor directly under the axle. Always prioritize stability.

Remove the Wheel: Unscrew the lug nuts completely and keep them in a safe place. Carefully remove the wheel. Having a helper can provide extra stability.

Inspect and Replace (or Repair): Examine the tire and tube (if applicable). Patch a repairable puncture, or replace a damaged tire with one of the same size. Replacing the tire yourself can save you up to $50 versus professional service.

Reassembly: Mount the new or repaired tire onto the rim. Then, carefully replace the wheel on the axle and screw on the lug nuts finger tight.

Lower and Tighten: Slowly lower the tractor. Once the wheel is on the ground, tighten the lug nuts completely using a star pattern to distribute pressure evenly. This helps to prevent uneven wear and tear on the wheel.

What Could Go Wrong (and How to Fix It): Troubleshooting

Stubborn Lug Nuts: Use more penetrating oil and let it sit longer. A breaker bar provides extra leverage. If you're still stuck, professional assistance is recommended.

Beyond Repair: A severely damaged tire requires replacement. Ensure you purchase the correct size tire. Always refer to the tire's sidewall for the exact size.

Jack Issues: Never overload your jack. If it feels unstable, stop immediately and use a heavier-duty jack or jack stands. A failing jack poses a significant safety hazard.

Safety First: Wrapping Up

Remember, safety is paramount. Take your time, double-check your work at each step, and don't hesitate to seek assistance if needed. Rushing increases the likelihood of accidents and damage. A little patience goes a long way. Did you know that 9 out of 10 lawn tractor incidents are related to improper tire changing procedures?